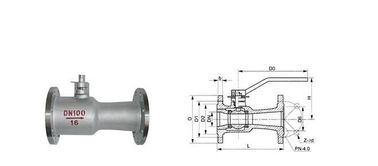

Unibody casting floating type ball valve of 2"-8" CL150-600 API 6D , 608 desgin

Unibody/split body, full bore/reduced bore, floating ball, fire-safe certified to API-607/6FA, anti-blow out stem, cavity relieving seats, anti-static device, RTFE, Delrin, NYLON&DEVLON seat inserts. Floating ball valves are designed, constructed and tested according to the most recent international standards, such as API, ASME, BS, DIN, etc.

Kelite unibody floating ball valves are including below components

1. Body

2. Closure / Cap

3. Ball

4. Cavity Relieving Seat

5. Stem

6. Anti-Static Spring and Ball

7. Gland Bushing

8. Gland Flange

9. Combination Lock Stop

10. Stem O-Ring

11. Gland O-Ring

12. Packing

13. Stem Thrust Washer

14. Graphite Gasket

15. PTFE Gasket

16. Gland Screw

17. Stem Washer

18. Stem Bolt

19. Stem Bearing

20. Gland Bearing

21. Snap Ring / Circlip

22. Handle

Kelite unibody and splid body floating ball valves has below design characteristic

Floating ball valves present a particular problem with the build up of static electricity around the ball. All Kelite ball valves have anti-static devices which provides contact between stem and ball, and stem and body to eliminate static electricity.

In the event of a fire the valve is required to make a downstream seal. Even after the disintegration of the RTFE seats, KELITE ball valves have an excellent metal to metal seal. Special attention has been paid to the mechanical strength and sealing efficiency of the central flanged joint in the valve body.

The PTFE gasket packing acts as a primary seal for the unibody ball valves. The secondary seal has been made out of flexible graphite, a material with extremely good resistance to fire conditions.

- BLOW-OUT PROOF STEM DESIGN

The combination of stem packingand o-rings guarantee zero emissions even at a low pressure. The primary seal is made out of flexible graphite, a material with extremely good resistance to fire conditions. The anti-blow out stem is inserted from inside the valve body.

Technical parameters and characteristics:

| Product description |

Side-mounted floating ball valve |

| Model |

Floating ball valve |

| Nominal diameter |

NPS 2~NPS 8 |

| Operating temperature |

-46℃~220℃ |

|

Operating pressure

|

CLASS 150~CLASS 600 |

| Material |

WCB,LCB,CF8,CF8M,etc. |

| Design standard |

API 608,ISO 17292,BS 5351 |

| Structural length |

ASME B16.10 |

| Connecting end |

ASME B16.5,ASME B16.25 |

| Test standard |

API 598, API 6D |

| Operation method |

Handle, worm, motor-drive unit, pneumatic drive unit |

| Application fields |

Water, petroleum and natural gas |

|

Other remarks 1

|

A locking device is provided to prevent misoperation of valve. |

| Other remarks 2 |

Valve stem flyout prevention structure design, to prevent accident due to flyout of valve stem caused by abnormal pressurization in the chamber |

| Other remarks 3 |

Fireproof and antistatic design |

| Other remarks 4 |

Full bore of valve convenient for pigging, of small flow resistance and high flow capacity |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!